Emerging Trends in Paintless Dent Repair Technology

Introduction to Paintless Dent Repair (PDR)

Paintless Dent Repair (PDR) has become a revolutionary method in the automotive industry, providing an efficient and cost-effective solution for minor dents and dings. Unlike traditional repair methods, PDR maintains the vehicle's original paintwork, which is crucial for preserving its value. As technology continues to advance, new trends in PDR are emerging, enhancing both the effectiveness and accessibility of this repair technique.

PDR is favored for its ability to restore vehicles without the need for repainting, making it a quicker and more environmentally friendly option. The process typically involves the use of specialized tools to gently push and massage the dent out from the underside of the body panel. As more innovations are introduced, the scope and precision of PDR continue to expand.

Technological Advancements in PDR Tools

One of the most significant trends in PDR technology is the development of advanced tools designed to improve precision and efficiency. High-tech lighting systems, such as LED and fluorescent lights, are now being used to identify and assess dents with greater accuracy. These lighting systems allow technicians to see even the smallest imperfections that may have been overlooked with traditional techniques.

Furthermore, innovations in tool design have led to the creation of ergonomic hand tools that provide better leverage and control. This enhancement not only reduces physical strain on technicians but also allows for more precise manipulation of the metal, resulting in a superior finish.

Integration of Artificial Intelligence and Machine Learning

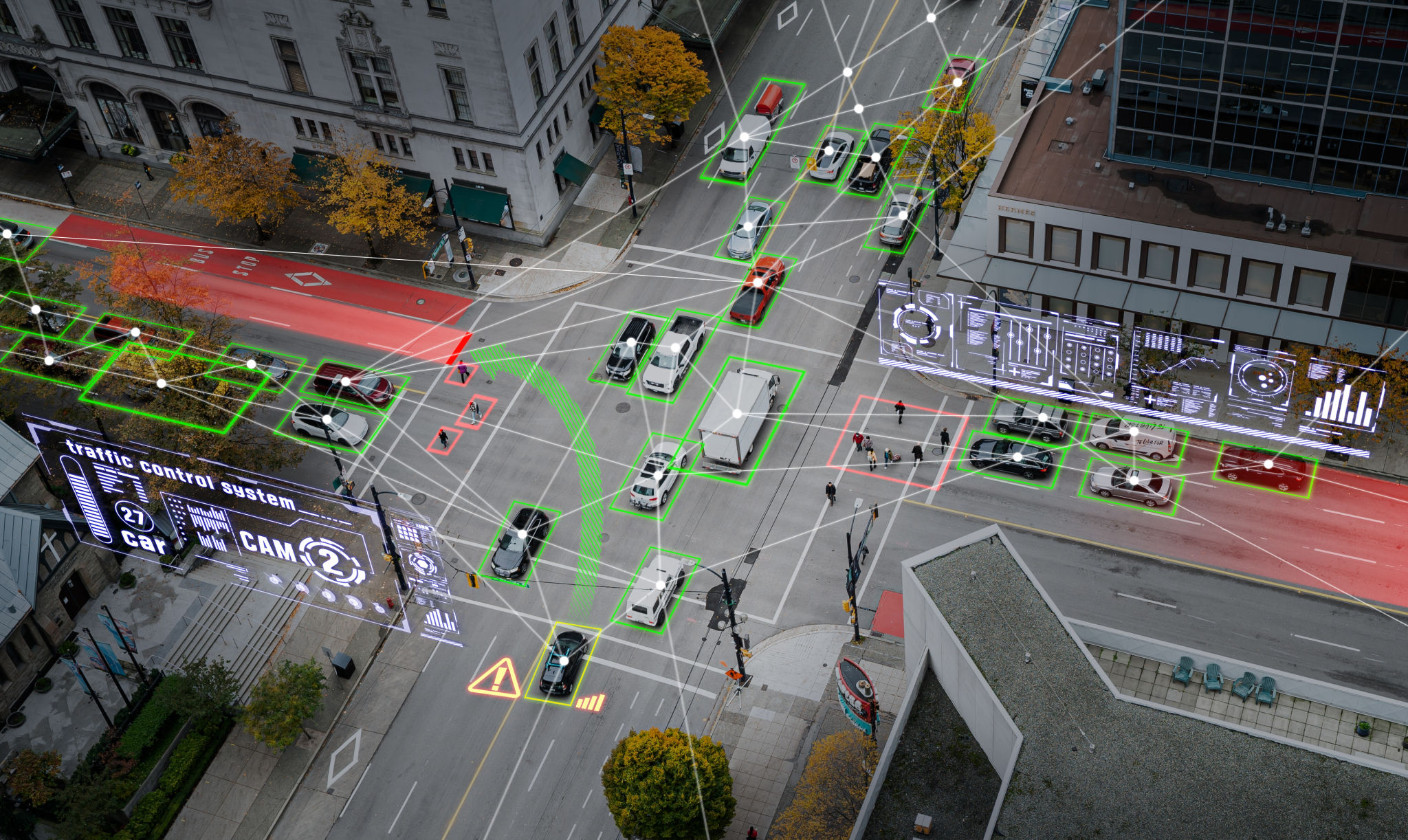

The integration of artificial intelligence (AI) and machine learning into PDR technology marks a significant leap forward. AI-driven software can analyze damage patterns and suggest optimal repair strategies, ultimately enhancing the speed and accuracy of the repair process. Machine learning algorithms can also aid in training technicians by providing real-time feedback and guidance during repairs.

Mobile PDR Services and Remote Diagnostics

The rise of mobile PDR services is transforming how consumers access dent repair. Equipped with portable tools and advanced diagnostic software, technicians can now travel directly to clients' locations, offering convenience and flexibility that was previously unavailable. This trend not only saves time for vehicle owners but also expands the reach of PDR services.

Remote diagnostics, enabled by cloud-based platforms, allow technicians to assess damage remotely and provide estimates before physically inspecting the vehicle. This capability streamlines the repair process and enhances customer satisfaction by setting clear expectations from the outset.

Sustainable Practices in PDR

As environmental concerns continue to influence industry practices, PDR stands out as a sustainable alternative to traditional repair methods. By eliminating the need for paint and harmful chemicals, PDR reduces the carbon footprint associated with automotive repairs. Additionally, advancements in biodegradable lubricants and eco-friendly tools are further minimizing the environmental impact of PDR operations.

The Future of Paintless Dent Repair

Looking ahead, the future of PDR appears bright, with continuous advancements promising to enhance its effectiveness and accessibility. The integration of virtual reality (VR) training programs is on the horizon, offering immersive learning experiences for technicians. These programs can simulate a variety of scenarios, allowing for improved skill development without the risk of damaging actual vehicles.

Moreover, as electric and autonomous vehicles become more prevalent, PDR technology will evolve to accommodate these changes. Specialized tools and techniques will be developed to address the unique materials and structural designs of these vehicles, ensuring that PDR remains a viable option for all types of automotive repairs.